Guangdong ABLinox Sanitaryware Co., Ltd. was established in year 2014. Formerly known as Foshan Yuejia

Hardware Factory in year 2008 to 2013.Now it is a High-tech

enterprise that integrates design,research and

development,production and export service.

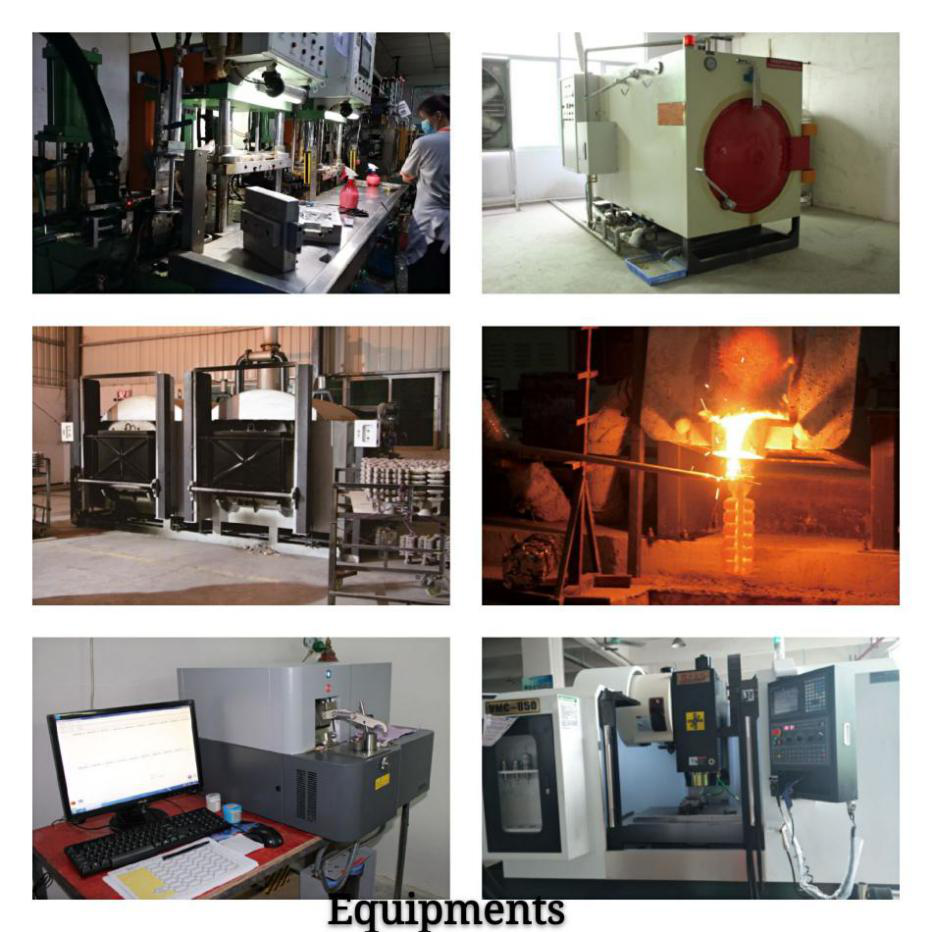

ABLinox is specilized in all kinds of stainless steel precious casting products.It is one of the few domestic enterprises in Stainless

Steel field that can process lost wax investment casting,machining and surface treatment all by itself.We provide One-Stop solutions for you have stainless steel

investment casting parts requirement.

ABLinox has cooperated with some TOP 500 enterprises.Our customers

are from the filed of Construction Hardware,Faucet,Shower,Marine Hardware,Food Machine,Fluid Equipment,Pume,Value,Auto,Air Filter,Liquid Filter,Aircraft,High speed Rail,etc.Our products are mainly exported to Europe and America market.

Mission: To become a Chinese Enterprise which is respected in the world

Vison: To become high-end custom expert in stainless steel field

Value: Creat customer value,Realize employee value

ABLinox builds win-win relationship with our clients,workers and

environment.Our team dedicated to strict quality control and

thoughtful customer service,our experienced staff are always

available to discuss your requirements and ensure full customer

satisfaction.Look forward to cooperate with you soon.